Aluminum Alloy High Pressure Die Casting with Precision CNC Machining

Basic Info

| Model NO. | Custom |

| Die Casting Machine Type | Cold Chamber Die Casting Machine |

| Die Casting Method | Precision Die Casting |

| Application | Auto Parts |

| Machining | CNC Machining |

| Material | Aluminum Alloy |

| Surface Preparation | Electroplating |

| Pressure Chamber Structure | Vertical |

| Tolerance Grade | 6 |

| Casting Surface Quality Level | 1 |

| Certification | CE, RoHS, ISO 9001:2000 |

| Mold Life | 100000PCS |

| Capacity | 50000PCS/Monthly |

| Finish | Polishing, Deburring, Painting, Sand Blasting |

| Die Casting Machine | 400~2500ton |

| Transport Package | Wooden Box |

| Specification | Customized |

| Trademark | Customized |

| Origin | China |

Packaging & Delivery

Package size per unit product 50.00cm * 50.00cm * 50.00cm Gross weight per unit product 30.000kgProduct Description

| Material Capabilities | Aluminum alloy A360, A380, A390, ADC-12,ADC-10, Zinc Alloy & Magnesium Alloy |

| Manufacture Process | Gravity casting, Low pressure die casting, High pressure die casting, Metal casting |

| Secondary Machining | CNC turning, milling, drilling, grinding, assembly to Packing |

| Surface Finish | Chrome plating, sand blasting, painting, anodizing, powder coating, electrophoresis etc |

| Casting Tolerance | CT6 - CT8 |

| Maximum Ton | 1800T (From 200T to 1800) |

| Application | Communication equipments, mechanical equipments, Auto Parts, Automation machine, medical device, industrial Machine, automobile, electric appliance, and other industries etc |

Company Profile

SIMIS CASTING, established in year of 2004, is a professional foundry, including integrating development and production together, specialized in producing various kinds of investment casting parts, and sand casting parts. These casting parts are widely used in automobile industry, railway vehicle, construction machine, municipal works, pipeline, petrochemical industry, mine, electric utility industry and so on.

SIMIS has six affiliated casting workshop and 2 professional CNC machining workshops. There are 500 staffs and 40 engineers now in our company. Its annual production capacity for all types of casting parts is about 3000 tons. Holding over 100 sets of advanced casting parts, machining and test equipments.It is also equipped with many advanced CNC machining center, CNC turning center, CNC milling machine and CNC lathes. It can do the heat-treatment, electricity polishing, mirror polishing and CNC machining at the request of clients.

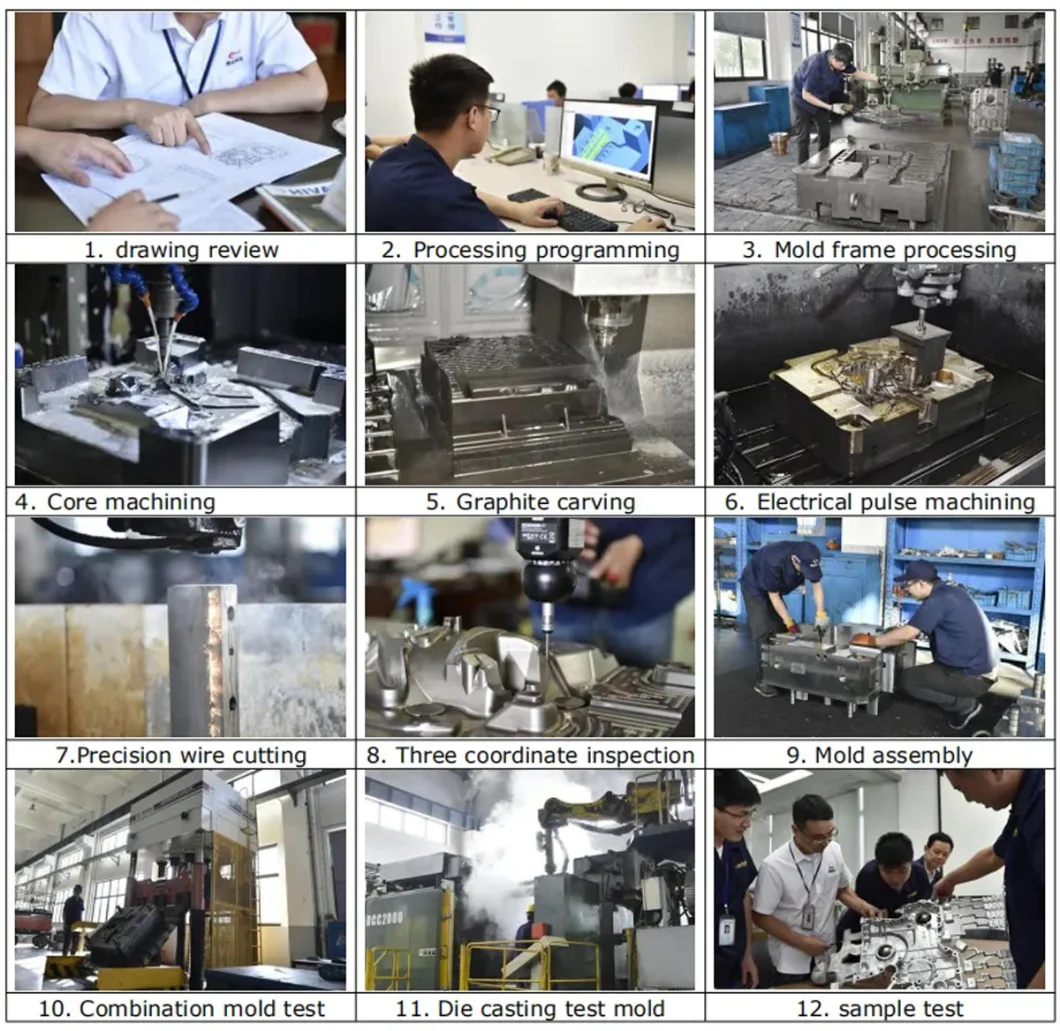

Production Process

Production Process

1. Lost Wax Casting Process * Investment casting : Silica Sol * precision casting : Silica Sol & Water glass * water glass casting

2. Sand Casting Process * Shell Mold Casting Process * Lost Foam Casting Process

* Resin Sand Casting Process

3. Die Casting Process * Low pressured die casting * High pressure die casting * Metal mold gravity casting

4. CNC Machining

Testing Ability

| Dimensional | Non-Destructive Tests(N.D.T.) | Chemical & Mechanical |

| Surface Roughness Test | Dye Penetrant | Chemical analysis |

| Microscopic Measurement | Radiography (RT) | Metallography |

| 3D Scanning | Magnetic Particle (MT) | Tensile Strength |

| CMM | Ultra-Sonic (UT) | Yield Strength |

| Impact Test | Hardness Test | Elongation Rate |

| Shrinkage Rate |

Surface Treatment

Application Field

We serve customers from many industries, such as aerospace, automation equipment, robotics, home appliances, communications equipment, automotive components, smart home appliances and medical equipment

FAQ

Q1:Are you manufactory or trade company?

A1:We are an enterprise integrating manufacturer and trade for many years already in Shanxi province, China. And we are AAA grade credit enterprise, and also we have cooperative plants to provide other services such as plating and coating . Q2: How could I get a free quotation?A2:Please send us your drawings by Alibaba or email. The file format is PDF / DWG / STP / STEP / IGS and etc. IF there are no drawings, we can make the drawings according to your samples! Q3:How to control quality? A3:First, all raw materials are inspected by the quality control department before they are put into storage. Second, during the casting process, three times of spectral analysis were performed at the front, middle and back respectively. Third, after the parts are cleaned, perform a first visual inspection to check whether the product has casting defects before sending it to the next process. Fourth, conduct a comprehensive QC inspection of each part before shipment, including chemical composition, mechanical properties and other specific tests. Transactions can be through Alibaba's trade assurance.Q4:Can we have our Logo or company name to be printed on your products or package? A4:Sure. Your Logo could be printed on your products by Hot Stamping, Printing, Embossing, UV Coating, Silk-screen Printing or Sticker.