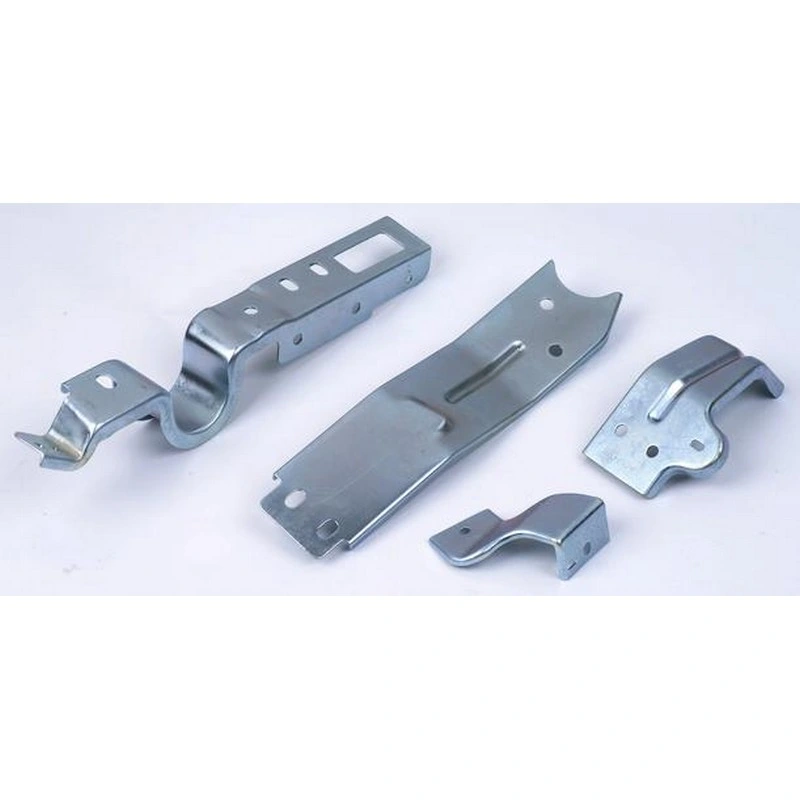

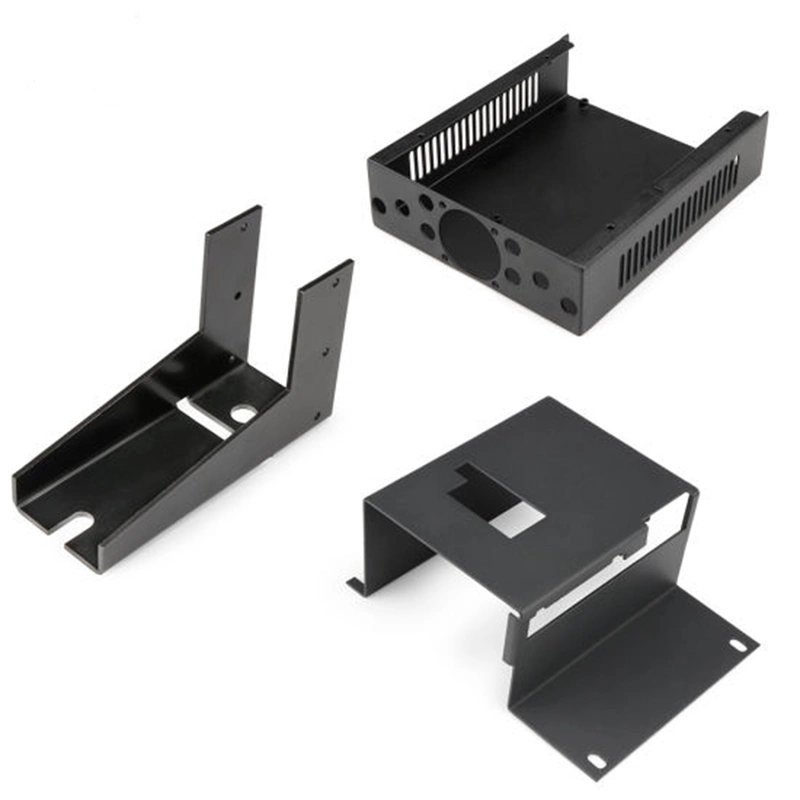

China Factory Custom Sheet Metal Stamping Service

Basic Info

| Model NO. | oem |

| Processing | Stamping and Bending |

| Quality Control | 100% Inspection Before Shipping |

| Shipment Terms | Express/Air Freight/Sea Freight |

| Color | Customized |

| Size | Customized |

| MOQ | Sample Available |

| Finish | Anodizing/Polish/Brush/Powder Coating/Plating/Ect. |

| Lead Time | Sample 5 Days, Production 15~25 Days |

| Brand | OEM |

| Transport Package | Standard Export Carton with Pallet |

| Specification | Sheet Metal Stamping Parts |

| Trademark | non |

| Origin | China |

| Production Capacity | 50000 Pieces Per Month |

Product Description

China factory Custom sheet metal stamping service

-These parts are customized, not in stock; We can produce based on your drawings or samples.-We can sign NDA(Non-disclosure Agreement) with you if you need;-Supplying Capacity: 50000 pieces monthly; small orders are welcome-Professional sales with engineering background

Welcome to send us your drawings or samples for the quotation~

| Available Material (Metals) | Available Material (plastic) |

| Alloy(aluminum, zinc, magnesium, titanlum) | ABS, PC, ABS, PMMA(acrylic), Derlin, POM |

| Brass, bronze, copper, beryllium | PA(nylon), PP, PE, TPO |

| Carton steel, stainless steel, SPCC | Fiberglass reinforced plastics |

| Processes | Surface treatment (finish) |

| Casting, CNC machining (turning / milling), Grinding | High polish, brush, sand blast, anodization |

| Sheet metal stamping, bending, welding, Punching | plating(nickle, chrome), powder coat, |

| Deep drawing, Spinning, assembly | Lacquer painting, silk screen, pad printing |

| Equipment | Quality control |

| CNC machining centers, casting machines | CMM(3D coordinate measuring machine), 2.5D projector |

| CNC turning centers / lathe / Grinders | Thread gauge, hardness, caliber |

| Punching, Spinning and Hydraulic tensile machines | Thrid party inspection available if required |

| Lead time & Packing | Application |

| 7~15 days for samples, 15~25 days for mass production | Automotive industry / Aerospace / Telecom equipment |

| 3~5 days via express: DHL, Fedex, UPS, TNT, ect | Medical / Marine / Construction / lighting system |

| Standard export carton with pallet. wooden case if needed | Industrial Equipment & Components, ect. |

Our Advantages

1. We offer one-stop solutions to our customer. Offer from designing, machining/fabricating, welding, surface treatment to finally assembly.2. Experienced engineers, precision machines, strict QC system to ensure quality. 3. Good communications. Our sales are professional with engineering background, it's easy to communicate with them about your products4. We are responsible to every customer of ours. Good pre-sales and after-sales service.5. Fast response to your requirements

Packaging & Shipping1. Paper, EPE Foam, poly bag, PP bag packaged for protecting products.2. Standard cartons with pallets or wooden cases3. Shipped by express, air, and sea are available4. We can pack and ship according to customer's specific requirements.

Q: Is it possible to know how my products are going on without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with pictures and videos which show the machining progress

Q: If you make poor quality goods, will you refund our payment?

A: As a matter of fact, we won't take a chance to send you poor quality products due to our quality control system.Meanwhile, we manufacture good quality products until your sastisfaction. We'll take responsibility for our customers.

A:Yes, we won't release your design to third party unless with your permission

Q: What can you buy from us?

A: Customized CNC machining parts, sheet metal parts, die casting parts, plastic injection parts, customized moulds

Q: How can I get a quotation?

A: Kindly send the details to our sales, including drawings, or samples pictures with size, material, quantity, surface treatment, other requirements, we'll quote accordingly within 24 hours.