a Large-Scale Professional Investment Casting Foundry with Powerful Machining Capabilities

Basic Info

| Model NO. | drag balance bracket of high-speed train |

| Surface Roughness | Ra12.5 |

| Machining Tolerance | +/-0.01mm |

| Standard | ASTM. AISI. DIN. BS. JIS. NF. as. AAR |

| Certification | ISO 9001:2008, Ts16949/ISO14001/TUV |

| Heat Treatment | Quench and Temper by 2 Set Mesh Belt Furnaces |

| Machining Facility | 30 Machining Centers+50 Nc Machines |

| Inspection | Mt/Ut/Rt/100% Visual+100% Gage/CMM |

| Dimensions | OEM Customized/Customer′s Drawing |

| Transport Package | Plywood Case or Iron Pallet Packing |

| Specification | drag balance bracket of high-speed train |

| Trademark | LX |

| Origin | Ningbo, Zhejiang, China |

| Production Capacity | 20000tons/Year |

Product Description

A large-scale Professional Investment Casting Foundry With Powerful Machining Capabilities

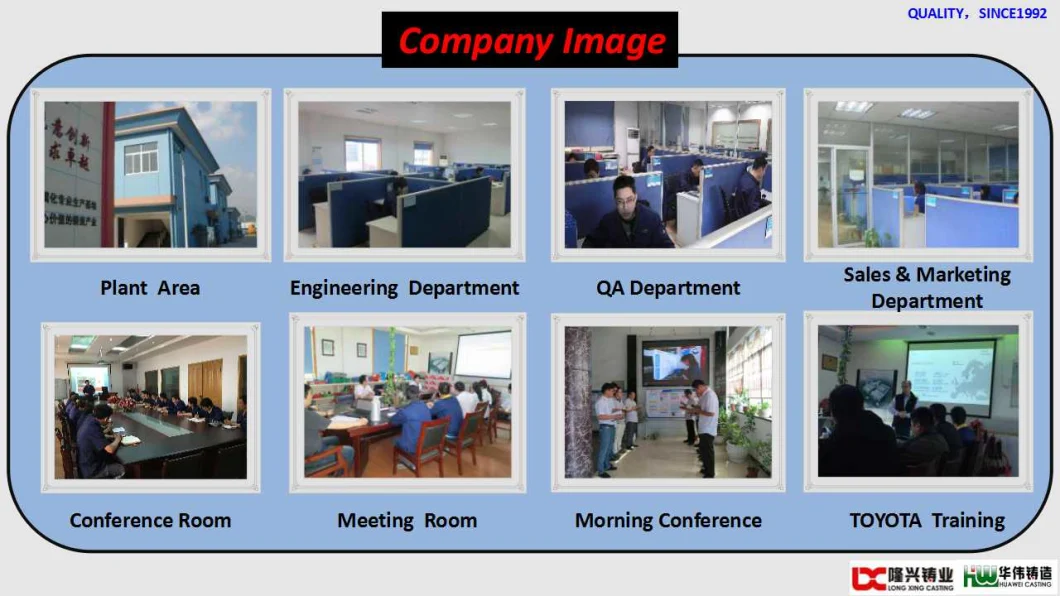

1. Company Profile:

Specializing in the manufacturing of lost wax investment castings and machined parts in carbon steel and alloy steel, our company is a large-scale professional investment casting foundry with powerful machining capabilities in China. It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply precision castings parts with annual capacity of over 20, 000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. Our company was established in 1993, it covers a total area of about 40,000 square meters and has about 400 employees.The headquarters is located in the famous industrial town Yinzhou, Ningbo in China. It is very convenient to be reached with an advantageous geographic position; It is located about 40 kilometers away from the Bei-lun Port which is the second biggest port in China, and about 25 kilometers away from the Lishe International Airport. The casting base is located in Fenghua, Ningbo, a distance of 20 kilometers away from the Headquarters. the foundry is equipped with several types of energy-saving & environmentally-friendly production lines including automatic or semi-automatic production lines of key processes: wax making, shell making, pouring, heat treatment. The machining factory is located in headquarters and is fully equipped with complete and advanced CNC machining equipment including 30 vertical and horizontal machining centers, and more than 30 CNC machines and 50 other machining equipments., the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. In addition to the casting, forging and machining, it also has the facility to machine various profiles. Our company also has a lot of advanced inspection equipment, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we are able to supply the high quality castings to our customers, and make products meeting comprehensive inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections. Our products cover a wide range of industries including train&Railway, automobile&Truck, construction machinery, mining machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. We are capable to produce products according to customers' drawings or samples, we focus on both carbon steel and alloy steel. Up to today, more than 100 raw materials and 5, 000 kinds of different products have been developed and produced by us. We are familiar with the material standards of many countries, such as Chinese GB, American ASTM, AISI, German DIN, French NF, Japanese JIS, British BS, Australian AS and Association of American Railroads (AAR ) and other industrial standards. |

2. History:

Since 1992

| 1992 | Ningbo Yinzhou Longxing Machinery Manufacturing Factory was established. Mainly engaged in machining. |

| 1999 | Renovation investment casting production lines in Longxing, production of precision casting, production capacity of 5000 tons. |

| 2001 | Obtained ISO9001: 2000 certificate. |

| 2003 | Products began to export. |

| 2005 | Ningbo Fenghua Huawei investment casting was established. |

| 2007 | Cooperating with Bombardier, first the OEM railway customer abroad. |

| 2008 | All casting production line moved to Huawei, supply capacity of 15000 tons. Cooperating with Hyundai motor company in North America, the first OEM automobile customer abroad. |

| 2009 | Ningbo Qianhao metal product was established. Mainly engaged in machining and import & export business. |

| 2011 | Obtained TS16949: 2009&ISO14001: 2004 certificate. |

| 2012 | Cooperating with Doosan in Korea, first the OEM construction machinery customer abroad. |

| 2013 | Huawei expanded production capacity ,supply capacity of 20000 tons. |

| 2014 | Establishing ERP production management system, implementation of 5S management. |

| 2015-2017 | Building production lines of automatic or semi-automatic wax and shell making ,pouring process in Huawei .More advanced environmental protection devices have been adapted. |

3. Overview of Factory---Huawei Investment Casting

|

4. Overview of Factory---Qianhao Machining (predecessor is Longxing machinery )

|

5. Our Mission:

Create the More Value for Customers, Contribute for Equipment Manufacturing in the World.

6. Our Values:

- Moving with the Times

- Pioneering and Innovation

- Harmony and Win-Win

- Striving for Excellence

7. Human Resources:

Working Style: Sincere pragmatic, Persistent effort, Teamwork, Struggle&Transcend

Employee Image: Elegant style, Polite and courteous, Warmly and humble, Be neither Arrogance nor Inferiority, Preciseness and Professional.

| Human resources | |

| Casting Engineers | 5 |

| Material Engineers | 2 |

| Heat Treatment Engineers1 | 1 |

| Machining Engineers | 5 |

| Professional Technician | 8 |

| QA | 40 |

| Production Managers | 36 |

| Administrative Administrator | 32 |

| Sales &Customer Service Staffs | 16 |

| Direct Labor | 260 |

| Total: 405 | |

8. Annual Turnover:

Expected Target: Up to 2020, annual turnover exceeds 60 million dollars

| Annual turnover(Unit: Million Dollars) | |

| 2005 | $ 7.4m |

| 2006 | $ 9.0m |

| 2007 | $ 12.6m |

| 2008 | $ 16.0m |

| 2009 | $ 10.7m |

| 2010 | $ 15.5m |

| 2011 | $ 18.4m |

| 2012 | $ 17.6m |

| 2013 | $ 26.9m |

| 2014 | $ 32.6m |

| 2015 | $ 34.1m |

| 2016 | $ 36.6m |

| 2017 | $40.1m |

9. Product Descripition:

| Casting Process | Water glass process of lost wax investment casting |

| Material | Carbon steel, alloy steel,stainless steel |

| Casting dimension tolerance | CT7-CT8 |

| Casting surface roughness | Ra 12.5um |

| Casting weight range | 0.1-100kg |

| Size | Max linear size: 1200mm, Max diameter size: 600mm |

| Machining Precision | Positioning accuracy 0.008mm, Rep. Position. Accuracy 0.006mm |

| Machining surface roughness | Ra0.8~6.3um |

| Max Travel Of Spindle | 1800mmx850mmx700mm |

| Max Turning Diameter | 1000mm |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR... |

| Applicable Fields For Our Product: | Train & railway, automobile& truck, construction machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine, hardware, power equipment and so on. |

10. Product Profile:

| 1. Marterial percentage | Alloy steel: 45% |

| 2. Casting weight percentage | 0.1-5kg: 40% |

| 3. Industry percentage | Components for train & railway: 20% |

| 4. Globa market share | United States: 30% |

| 5. Supply capacity | Production Capacity: 20, 000 tons / year |

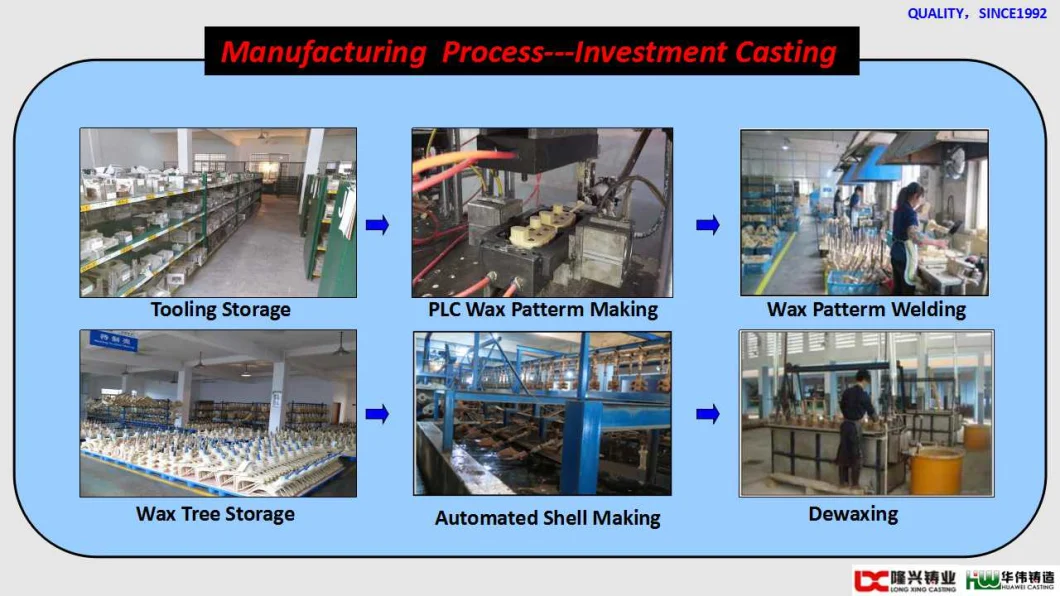

11. Manufacturing Process:

Process design⇒ Tooling making ⇒ Wax injection ⇒Wax pattern assembly⇒ Mold preheat ⇒ Wax removal ⇒Stuccoing ⇒Dipping Casting⇒ Mold shake out ⇒Work piece cut-off ⇒ Grinding ⇒ Pack& transport ⇒ Final inspection ⇒Machining ⇒ Heat treatment

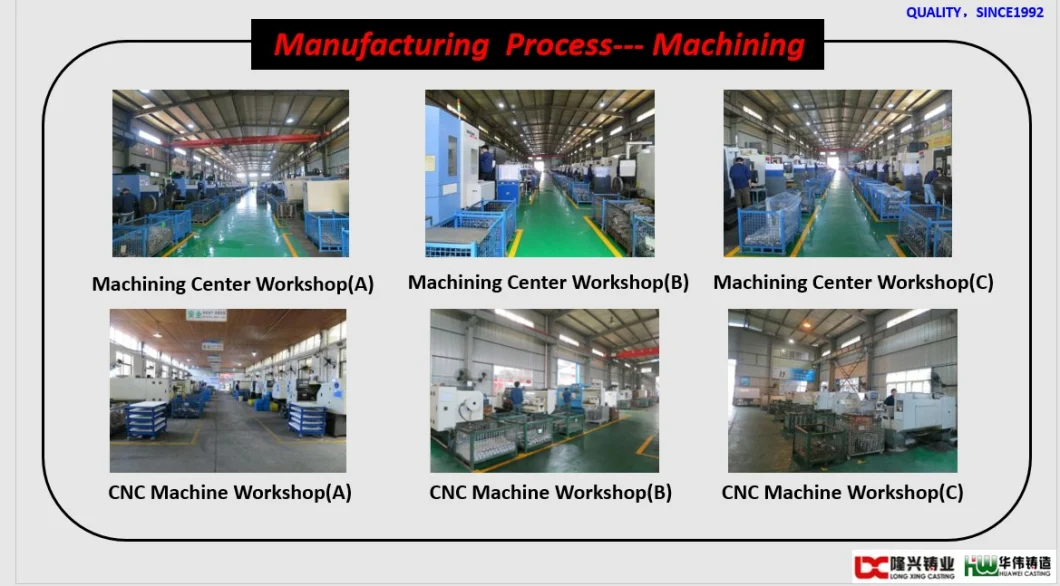

12. Major Machining Equipment List:

| Machining Capabilities | |

| Three-Axis turning centre: 1 | Four-Axis Vertical Machine Center: 28 |

| Four-Axis Horizontal Machine Center: 1 | CNC Milling Machine: 6 |

| Vertical Lifting Milling Machine: 4 | Universal Milling Machine: 2 |

| Plane Milling Machine: 2 | Fase Milling Machine: 3 |

| CNC Lathe Machine: 27 | Oblique Guide CNC Lathe Machine: 2 |

| Engine Lathe Machine: 6 | Special Lathe: 5 |

| Radial Drilling Machine: 4 | CNC Porous Drilling Machine: 6 |

| CNC Spacial Drilling Machine: 2 | Cylindrical Drilling Machine: 11 |

13. Key Testing Equipments:

| 1. Direct-Reading Spectrometer | 12.3D Scanner |

| 2. Non-contact infrared thermometer | 13. Coordinate Measuring Machine |

| 3. Metallographic Microscope | 14. Surface Roughness Tester |

| 4. Tension Tester | 15. Ultrasonic Testing Machine(HS600) |

| 5. Low Temperature Chamber For Impact Specimen | 16. Coating thickness gauge |

| 6. Impact Test Machine | 17. Portable Magnetic Particle Tester |

| 7. Magnetic Particle Testing Machine | 18. Portable Hardness Tester |

| 8. Ultrasonic Testing Machine | 19. Hardness Test Machine |

| 9. X-ray tester | 20. Rockwell Hardness Test Machine |

| 10. Surface Roughness Tester | 21. Contact infrared thermometer |

| 11. Video Measurement Machine |

14. We provide various test facilities as mentioned under:

| 1. Chemical analysis |

| 2. Tensile strength |

| 3. Elongation rate |

| 4. Shrinkage rate |

| 5. Impact test |

| 6. Harness test |

| 7. Metallography |

| 8. Non-destructive tests(including dye-penetrant, ultrasonic, magnetic particle and radiography) |

| 9. Surface roughness test |

| 10. CMM test |

| 11.3D scanner |

15. APQP and Inspection Report:

APQP-Casting

|

APQP-Machining

|

Inspection Report-Casting

|

Inspection Report-Machining

|

Other Quality Document

|

16. Competition Advantages:

Advantages 1: High Engineering and Technical Capability

- An industry's senior engineering technical team, with special skills and rich experience in product design, casting, heat treating and machining fields.

- Based on customer needs, in the beginning of product development, offer a solution, casting design, by structural component designed to casting parts, optimize the product design, then reduce costs and creating the more

value for the customers. - Special Techniques Enable LONGXING to Be Competent with Those Difficulties at Wax Injection & Shell Making Procedures When Manufacturing the Parts with Inner-Sophisticated-Structures.

- Use casting simulation analysis system software , try our best to ensure the success of the one-time trial sample.

- Our testing equipments are not only advanced in the industry, and also has a very complete range, they are hardware guarantee to ensure us continue to provide high-quality products for our customers.

- Carrying out ISO9001 and TS16949 quality management system, full implementation of 5S and Kanban site management, which is software guarantee of the quality.

- IQC, IPQC and FQC quality management team to control the whole production process, effectively prevent the generation of unqualified product.

- Our casting' PPM ≤7500 Machining ' PPM ≤1200.

- We stick to the quality management philosophy that "Starting from the customer needs and ending with their satisfaction, focusing on customer demands and exceeding their expectations".

- LONGXING can provide customers with good service, our staff have abundant commercial experience, good language ability, and rich foundry or mechanical background. We are committed to providing customers with accurate, careful and speedy service.

- Quotation, Quality Complaints and Email Response can usually be quickly and efficiently feedback within 48 hours.

- We have carried out an information-based management which is driven by an ERP and PMC system, to ensure on time delivery rate: 95%

It is our core competitive ability in the industry

- Machining capability as the same as casting, the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit.

- Enterprise has completed a transformation and upgraded to a deep-processing manufacturer with expanded production capabilities and is committed to be equipped with other capabilities except casting, we focus on developing terminal products for top-end markets.

- High technical content in machining, and casting with sheet metal, welding, assembling, LONGXING has the more

competitive advantage, it is the very good choice for you.