0.1kw - 250kw AC Servo Motor Controller Kit Servo Motor Drive System

Basic Info

| Model NO. | VEICHI SD700 |

| Task | Adjust |

| Structure | Combination |

| Mathematical Model | Linear |

| Signal | Continuous |

| Function | Automatic Control |

| Certification | CE |

| Condition | New |

| Customized | Non-Customized |

| Material | Aluminum Alloy |

| Transport Package | Carton Box/Wood |

| Trademark | VEICHI |

| Origin | Suzhou, China |

| Production Capacity | 600, 000 PCS/Year |

Product Description

>>> SD700 Series High-Performance Servo System Overview

VEICHI SD700 series servo drives are high performance, high reliability, high quality, and cost-effective products to meet a variety of industrial environments and critical system applications and achieve the perfect combination of servo and program.

>>> SD700 high-performance general-purpose servo--A complete fusion of sophistication and simplicit

- The speed loop response bandwidth can reach 3kHz.

- Using a 23-Bit absolute encoder, the communication speed can reach 2.5Mpps.

- Bandwidth setting, automatically complete PID loop gain calculation.

- Powerful PC software, multi-channel monitoring, easy to use.

- Automatically complete inertia identification, loop gain, friction compensation, and other parameter settings.

- Support multi-stage vibration control function, effectively limit resonance.

- Robust control ensures smooth operation of loads with inertia within 30 times.

- New structural appearance design, compact and space-saving.

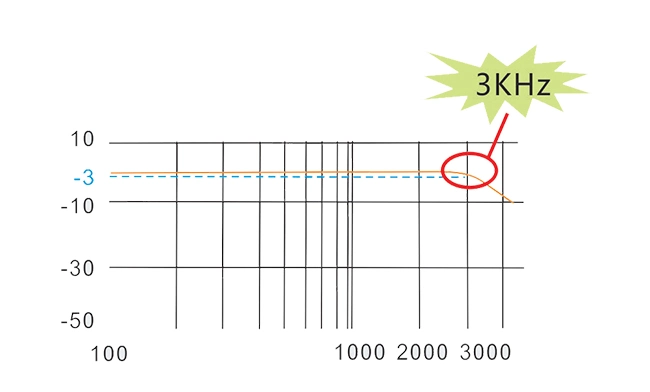

>>> 3kHz speed loop response bandwidth

Through the unique current loop algorithm, the bandwidth of the speed loop is effectively increased, and the setting time is greatly shortened. The fastest setting time can reach 1ms, which improves production efficiency.

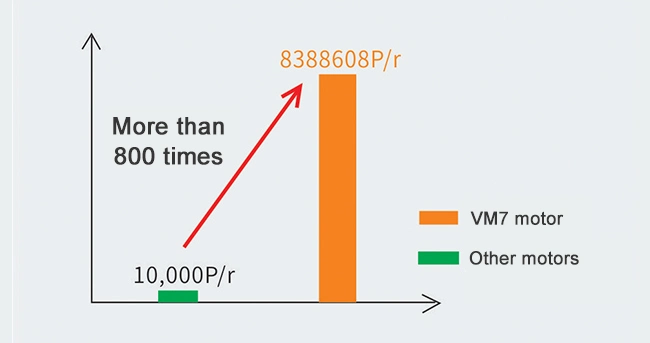

>>> 23-Bit absolute encoder

- Standard 23-Bit multi-turn absolute encoder, single-turn up to 8388608 pulses, communication speed up to 2.5Mpps.

- The positioning is more accurate, the low speed is more stable, and the power-off position is not lost.

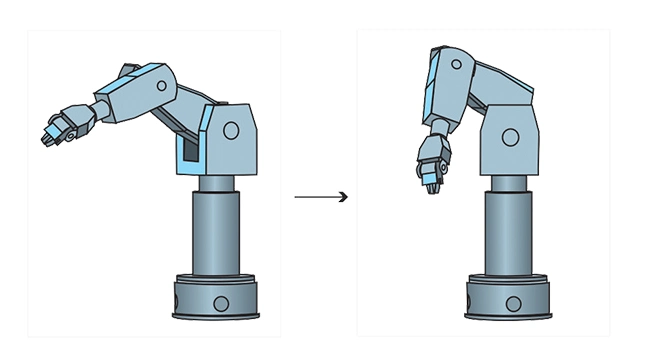

>>> Robust control

- The new control theory algorithm is adopted to realize that even if the load moment of inertia changes within 30 times during the movement, there is no need to set the slave parameters to ensure smooth operation.

- It can be used after installation. This function is widely used in manipulators.

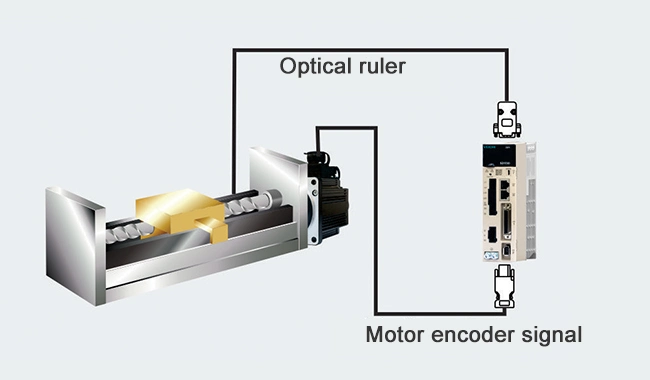

>>> Support full closed-loop mode

The fully closed-loop mode supports an external second encoder or grating ruler, which reduces errors caused by the mechanical transmission gap and improves positioning accuracy. All models are equipped with this function.

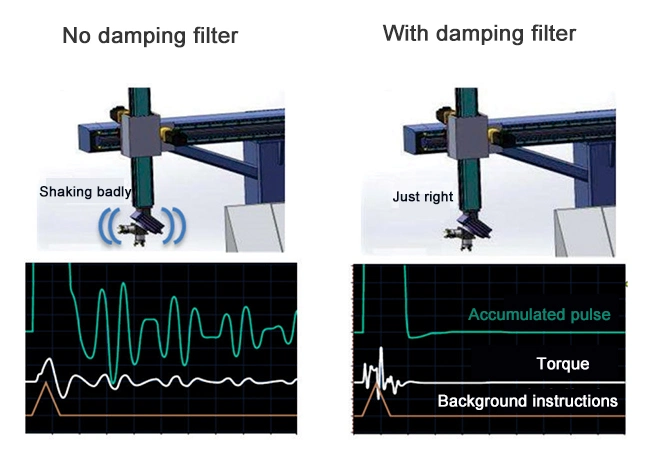

>>> The low-frequency vibration control function

The damping filter can be set through the host computer software, which can effectively eliminate the inherent vibration frequency, greatly reduce the vibration (shaking) of the shaft when stopping, and can effectively suppress the vibration of 0~100Hz frequency. This function is commonly used to eliminate injection molding robots and stackers The end shakes when stopped.

>>> Automatic setting of the notch filter

- There is no need to perform complex vibration frequency measurement and analysis, and the notch filter can be quickly searched and automatically set during the parameter tuning process through the single parameter adjustment function of the host computer.

- Simple and easy to use, the fastest does not exceed 70ms. It can greatly reduce the noise and vibration caused by the mechanical resonance of the equipment, to achieve a faster response action. This function is widely used in machine tools.

>>> Smart setting

Automatic gain adjustment, guided setting mode, the sequential setting can complete the setting of servo gain, simple and easy to use. Provides more adjustment modes, which can be adjusted according to different mechanical structure and process characteristics, so that the machine can reach a suitable state.

>>> Powerful bus communication function

Support RS-485, EtherCAT, CANopen, MECHA-METROLINK, MECHATROLINK, and other mainstream buses.

>>> Greatly reduce the pulsating torque of the motor, and the low-speed operation is more stable

It adopts a 10-stage rotor and 12-slot spindle design. Through a special magnetic circuit design, the cogging effect is effectively suppressed and torque ripple is greatly reduced, thereby ensuring that the motor runs more smoothly at a constant speed and low speed.

>>> Powerful PC software

- No need to install and debug software.

- USB communication between the drive and the computer, easy to use.

>>> Industrial Applications for SD700 Series High-Performance Servo System

Applications: Electronic manufacturing equipment, numerical control equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.

>>> Specifications

| Project | Specifications | ||||||

| Power range | 0.1kW - 55kW, customized up to 250kW | ||||||

| Control mode | IGBT, PWM control and sine wave current drive mode | ||||||

| Feedback | Rotary motor combination | Serial communication encoders: 17-bit, 20-bit and 24-bit (absolute encoder) | |||||

| Pulse encoder: provincial linear encoder-2500 lines | |||||||

| Rotary transformer type encoder | |||||||

| Environmental conditions | Environment temperature | Environment temperature: -5ºC-55ºC (reduce the use of ratings when it's 55ºC-60ºC) | |||||

| Storage temperature | -20ºC~85ºC | ||||||

| Operating environment humidity | less 95% RH (without freezing or frosting) | ||||||

| Storage humidity | less 95% RH (without freezing or frosting) | ||||||

| Vibration resistance | 4.9m/s² | ||||||

| Impact resistance | 19.6m/s² | ||||||

| Protection level | IP20 | ||||||

| Cleanliness | No corrosive and flammable gas | ||||||

| No water, oil and pharmacy splash | |||||||

| Used in less dust, salt and metal powder environment | |||||||

| Altitude | less 1000m (you can reduce the use of ratings when it's 1000-2000m) | ||||||

| Others | No static electricity interference, strong electric field, strong magnetic noise, radiation, etc. | ||||||

| Applicable standard | EN 61800-5-1:2007 EN 61800-3:2004/A1:2012 | ||||||

| Installation type | Base mounting type: all models | ||||||

| Shelf mounting type: all models | |||||||

| Performance | Speed control range | 1:6000 (the lower limit of the speed control range is the value under non-stop condition at the rated torque load) | |||||

| Speed fluctuation rate | Load fluctuation | Less ±0.01% of rated speed (load fluctuation: 0%-100%) | |||||

| Voltage fluctuation | 0% of rated speed (±10% of rated voltage) | ||||||

| Temperature fluctuation | Below ±0.1% of rated speed (temperature fluctuation: 25±25°C) | ||||||

| Torque control accuracy | ±1% | ||||||

| Soft-start time setting | 0~10s (acceleration and deceleration can be set separately) | ||||||

| Communication function | RS-485 | 1:N communication | When using RS-485 port, N max = 127 stations | ||||

| Axis position setting | Through parameter setting | ||||||

| USB communication | Connected equipment | Computer | |||||

| Protocol | According to USB1.1 specification (12M) | ||||||

| Display function | Charge indicator | ||||||

| Panel operation function | Push button switch × 4 | ||||||

| Input and output signals | Encoder divider pulse output | A-phase, B-phase and C-phase: linear drive transmission frequency pulse number can free to set | |||||

| Sequence input signal | Fixed input | Operating voltage range: DC 5V±5% | |||||

| Input points: 1 point | |||||||

| Encoder absolute data request input (SEN) signal | |||||||

| Assignable input signal | Operating voltage range: DC24V±20% | ||||||

| Input points: 9 points | |||||||

| Input method: common collector input and common emitter input | |||||||

| Input signal | |||||||

| Servo ON (/S-ON) | |||||||

| P operation/P-CON | |||||||

| Home reset deceleration switch signal (/DEC) | |||||||

| Forward drive prohibition (P-OT) and reverse drive prohibition (N-OT) | |||||||

| Alarm reset (/ALM-RST) | |||||||

| Forward external torque limit (/P-CL) and reverse external torque limit (/N-CL) | |||||||

| Speed rotation direction selection (/SPD-D) signal | |||||||

| Control mode switch (/C-SEL) | |||||||

| Zero position fixation (/ZCLAMP) | |||||||

| Command pulse disable (/INHIBIT) | |||||||

| Magnetic pole detection input (/P-DET) signal | |||||||

| Gain switching (/G-SEL) | |||||||

| Command pulse input override switch (/PSEL) | |||||||

| SEN input (/SEN) signal | |||||||

| Assignable signals and changeable positive/negative logic | |||||||

| Sequential output signal | Fixed output | Operating voltage range: DC5V~30V | |||||

| Output points: 1 point | |||||||

| Output signal: servo alarm (ALM) | |||||||

| Assignable output signal | Operating voltage range: DC5V~30V | ||||||

| Output points: 3 points | |||||||

| Input method: opt coupler output (isolated type) | |||||||

| Output signal | |||||||

| Positioning completed (/COIN) | |||||||

| Rotary checkout (/TGON) | |||||||

| Servo ready (/S-RDY) | |||||||

| Torque limit detection (/CLT) | |||||||

| Speed limit checkout (/VLT) | |||||||

| Brakes (/BK) | |||||||

| Warning (/WARN) | |||||||

| Locate nearby (/NEAR) | |||||||

| Assignable signals and changeable positive/negative logic | |||||||

| Dynamic brake | Operation in the main circuit power OFF, servo alarm, servo OFF and over-travel (OT) | ||||||

| Regenerative | Built-in function | ||||||

| Over-travel (OT) protection | Dynamic brake (DB) stop, deceleration stop or free-running stop during P-OT or N-OT input operation | ||||||

| Protective function | Over-current, over-voltage, under-voltage, overload, regenerative faults, etc. | ||||||

| Accessibility function | Gain adjustment, alarm records, JOG operation, origin search, etc. | ||||||

| Security function | Input | STO: base of the power module block signal | |||||

| Control method | Position Control | Feed forward compensation | 0%~100% | ||||

| Location reach arrange | 0~1073741824 instruction unit | ||||||

| Input signal | Command pulse | Command pulse form | Choose any of the followings | ||||

| Symbol & pulse sequence, CW+CCW pulse sequence, 90° phase difference and two-phase pulse | |||||||

| Input form | Linear drive and open collector | ||||||

| Maximum input frequency | Line driver | ||||||

| Symbol + pulse sequence, CW + CCW pulse sequence: 4Mpps | |||||||

| 90° phase difference two-phase pulse: 1Mpps | |||||||

| Open collector | |||||||

| Symbol + pulse sequence, CW + CCW pulse sequence: 200Kpps | |||||||

| 90° phase difference two-phase pulse: 200Kpps | |||||||

| Input override switch | 1~100 times | ||||||

| Clear signal | Position deviation clearing | ||||||

| Speed control | Soft-start time setting | 0~10s (acceleration and deceleration can be set separately) | |||||

| input signal | Command voltage | Maximum input voltage: ±10V (forward rotation of motor when positive voltage is commanded) | |||||

| Rated speed at DC6V [factory setting] | |||||||

| Changeable input gain setting | |||||||

| Input resistance | About 14KΩ | ||||||

| Loop time parameter | 30μs | ||||||

| Internally set speed control | Rotation direction selection | Use P operation signal | |||||

| Speed selection | Using forward/reverse external torque limit signal input | ||||||

| Stop or change to other control mode when both sides are OFF | |||||||

| Torque control | Input signal | Command voltage | Maximum input voltage: ±10V (positive rotation of motor when positive voltage is commanded) | ||||

| Rated speed at DC6V [factory setting] | |||||||

| Changeable input gain setting | |||||||

| Input resistance | About 14KΩ | ||||||

| Loop time parameter | 16μs | ||||||

>>> About VEICHI